Pori recovers valuable metals from overlooked sources

Electric cars, smart devices, the development of telecommunications and artificial intelligence – our present lifestyle in its entirety is founded on valuable metals. The problem, however, is access to them and, from a European point of view, our dependence on other continents. Pori residents are also looking for and finding copper, nickel, gold and other earth metals of importance in modern times from scrap and slag.

When in the post-war years Finland was struggling with energy shortages, the Satakunta area offered the solution. In 1949, Petri Bryk, who worked at the Outokumpu Harjavalta factory, created a flash smelting method for copper that has played a crucial role not only in the rise of the whole of Finland after the wars but also in the present and future of the Pori region.

Another thing the region inherited from Outokumpu is Boliden Harjavalta, one of the major metal industry companies still operating in the Pori region. Its history in Satakunta dates back to 1941. Outokumpu already had copper refining activities in Pori at the time. To evade the turmoil of the Continuation War, the company’s copper works were transferred from Imatra to Harjavalta, where they have remained for 80 years and counting.

The company, today known as Boliden, refines metal not only from blasted rock but, to an increasing extent, also from recycled raw materials. The company produces copper and nickel for further processing for the needs of the electrifying world. The circular economy of important and valuable metals is one of the cornerstones of the Pori region, which enables our present and future lifestyles one copper thread at a time.

The Holy Grail rises from molten metal?

We need increasing amounts of different earth metals to keep our cars moving, phones functioning, AI buzzing and factories running. The metal industry is also one of the most significant sources of climate emissions in the world. In fact, companies that need different metal alloys require increasing amounts of recycled and more environmentally friendly copper and other metals.

To ensure that the metal being processed is of as high quality and uniformity as possible, its processor should know what the raw material contains. For the time being, it has been anybody’s guess what recycled scrap and other materials may contain.

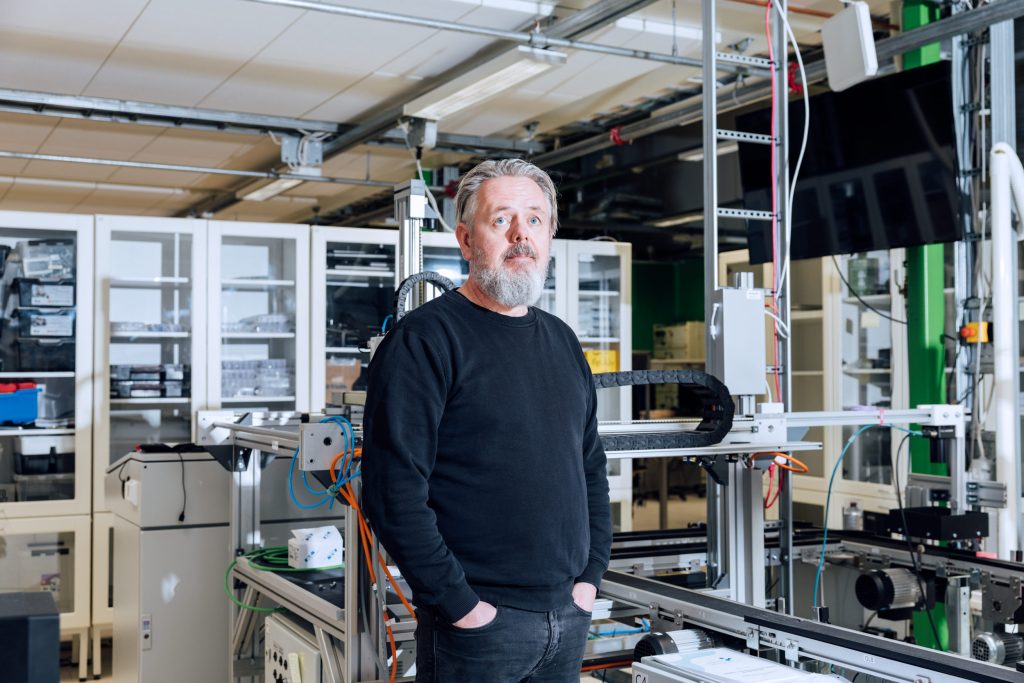

“For example, if Boliden receives a shipload of copper concentrate, almost every shovelful contains the same elements. The recycled raw material shipped in large bags, on the other hand, may contain a different array of materials every time. Adjusting the process is challenging even when using ores of uniform quality, but when it comes to recycled materials, the challenges are at a totally different level,” says Pekka Suominen, Senior Research Scientist from the RoboAI research group at Satakunta University of Applied Sciences (SAMK).

For this reason, SAMK and Boliden collaborated in a joint SUMEA project to study the possibilities of processing molten metal in a way that enables improved identification of harmful substances and metals in lower concentrations. Earlier, it has been possible to measure such concentrations from gases and liquids but not from molten metal.

Measuring is extremely difficult due to the high temperatures needed to smelt metal. The temperature of molten metal can be up to 1,400 degrees, and hardly any devices can withstand such heat. In SUMEA, we set out to develop analytics that, combined with AI, would allow identifying with increased accuracy what the alloy contains and how it could be processed in the best possible way.

The project also involved the RoboAI Research Centre, which was established jointly by SAMK and the University of Tampere in 2019. The centre studies, among other things, the circular economy of technology metals as well as AI, automation and robotics.

A key method used in molten metal research is laser spectroscopy. It is another field in which Pori residents have long traditions and solid expertise.

Using laser, the beam of light can be targeted to virtually any material. The radiation emitted by it, on the other hand, can be analysed utilising, for example, AI to find out what substances the material contains. The key to success is being able to measure the red-hot material from a safe distance.

“No other methods for measuring molten metal have been invented yet, so if we can get it working on an industrial scale, it is like finding the Holy Grail. At the same time, we have been examining how Satakunta could benefit from this technology in the future,” says Pekka Suominen.

The requirements for clean metals are increasing, but the quality of the reserves is weakening

Boliden is also increasingly using electronic waste and recycled materials from other industries in its production. What materials have in common is that they contain copper or other precious metals that can be separated from them, but it is not an easy process.

In practice, Boliden separates pure gold, silver or copper from the waste, and the company’s customers process them into, for example, copper wire for electrical cables or other components.

“Regarding copper, Boliden was the first company to launch so-called low-carbon copper, and recycled copper is part of our product range,” says Petri Latostenmaa, who acts as R&D manager at Boliden Harjavalta.

However, providing low-carbon materials alone is not enough – for example, the automotive industry has very high requirements for the purity of copper. The more sensitive the technology, the purer metal it requires. However, in recycling, purity unavoidably suffers. And the more recycled materials there are in the process, the more challenging it is to manage, Pekka Suominen points out.

“In recycled copper, certain impurities gradually increase. The quantities are very small, but when talking about cutting-edge equipment, even minor contaminants can cause problems. For example, using the material for electrical cables in a single-family house may not cause problems, but with accurate sensors it is a totally different story.”

Another major challenge is that high-quality ore deposits are running out in the world, and the best ore bodies have already been depleted. The raw materials in use are increasingly difficult to process, regardless of whether they are excavated or recycled.

“We don’t compete with each other; we support each other’s success”

Although the processes are not ready yet, the people of Pori have decided to continue paving the way for the new future of the metal industry. There is still room for further research.

“Improved identification of the content of molten metal would enable us to make our production more efficient. Although the SUMEA project has ended, we are contemplating how to proceed from here. In order to move forward in this matter, we need a commercial partner who would take up the development of measuring devices,” Petri Latostenmaa says.

Teemu Heino, Development Manager of the City of Pori, praises that these are not the first inventions made in the Pori region to reduce the carbon footprint. One example of this is the flash smelting method for copper, which was introduced in Harjavalta in the 1940s. It played a major role in reducing the carbon footprint of the industry even before the current climate debate began.

Heino calculates that the metal sector provides direct employment to an estimated 2,600–2,800 people in the Pori region. If the region’s all metal-related industries, including the technology industry, shipyards and engineering workshops, are included, the number will rise to more than 10,000. Satakunta’s metal competence is also significant for the whole of Finland.

“Satakunta only accounts for four per cent of the Finnish population, but we produce almost eight per cent of the value of exports. Even today, we have significant RDI activities in the metal sector, and our companies are competing in the world market. Almost everything we manufacture here is exported,” Heino says.

Petri Latostenmaa also praises the community spirit of the region and the field. In a strong network, everyone supports each other.

“The SUMEA project involved not only higher education institutions but also companies from different parts of the field, both technology companies and copper processors. We don’t compete with each other; we support each other’s success.”

Pori is a member of the InnoCities network. The leading development themes for Pori are technology metals, the circular economy, automation and robotics.

Want to know more Finnish miracles? Subscribe to InnoCities newsletter (published 3-4 times / year) from below!